In aerospace manufacturing, even minor defects can compromise structural integrity and result in costly rework or component rejection. Achieving zero-defect manufacturing therefore requires more than advanced production technologies; it demands inspection strategies that are tightly integrated into the manufacturing process and capable of providing timely, actionable feedback.

Composite structures are inherently complex, and typical manufacturing-related defects, such as gaps, overlaps, fiber misalignments, or internal porosity (void content), may originate during AFP and ATL processes. When inspection is performed only at the end of the production chain, defects are often detected too late, increasing technical risk, material waste, and overall production costs.

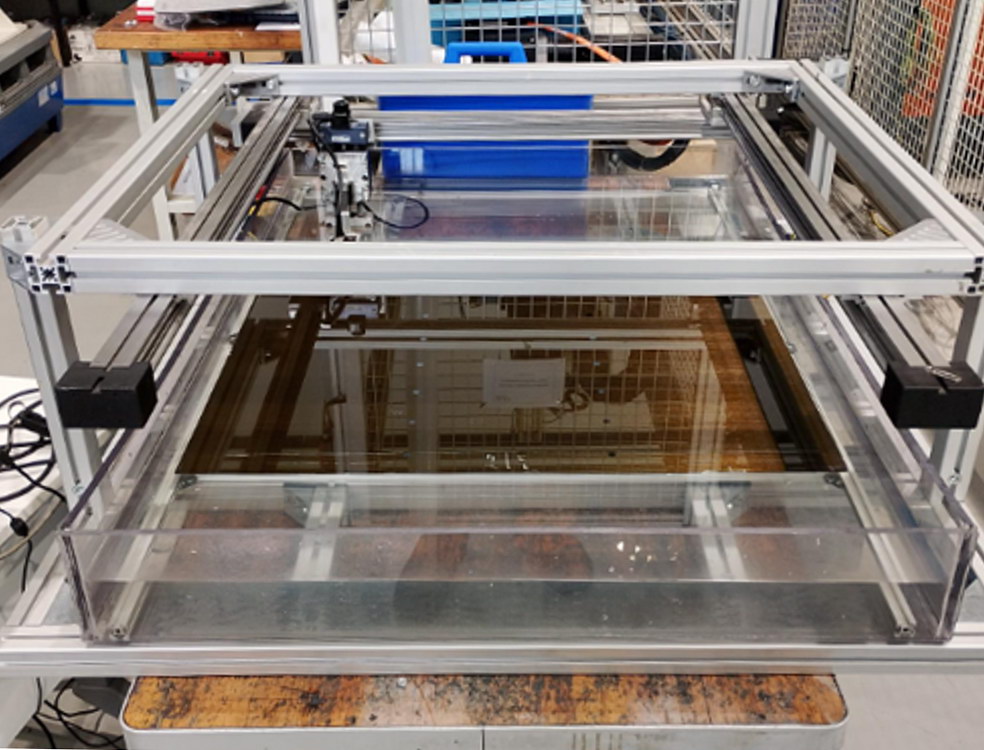

One particularly challenging issue is the detection of porosity in very thin composite laminates manufactured using in-situ ATL processes. In such cases, the limited laminate thickness and the low acoustic contrast between sound material and small porosity levels significantly hinder defect detectability using conventional inspection approaches. Figure 1 illustrates a representative CFRP microstructure where porosity is present, highlighting the subtle nature of these defects.

Figure 1

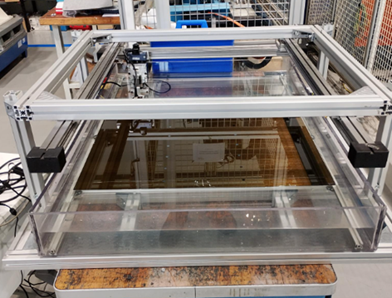

Within the CompSTLar project, dedicated efforts are underway to address this challenge through the development and adaptation of advanced non-destructive testing (NDT) strategies. These approaches aim to improve sensitivity to porosity while remaining compatible with in-situ inspection constraints. Figure 2 presents a pulse-echo ultrasonic testing (UT) inspection system for CFRP components, representative of the type of inspection technologies being investigated and optimized within the project.

Figure 2

By combining advanced composite manufacturing with intelligent inspection solutions, CompSTLar supports the transition towards integrated, zero-defect-oriented production workflows. Within the project, IDEKO contributes its expertise in non-destructive testing of CFRP structures, focusing on inspection approaches that are robust, industrially viable, and suitable for deployment in real manufacturing environments.