The Evolution of Aircraft Maintenance

Aircraft maintenance is fundamental to ensuring safe, reliable, and efficient aviation operations. Over the decades, maintenance strategies have evolved in response to increasing aircraft complexity, higher fleet utilization rates, and growing cost and sustainability pressures.

Traditionally, aircraft maintenance relied on Reactive and Preventive approaches. Reactive maintenance, or run-to-failure, addresses issues only after a failure has occurred. While acceptable for certain non-critical components, this strategy exposes operators to unplanned Aircraft-on-Ground (AOG) events, operational disruptions, and elevated costs.

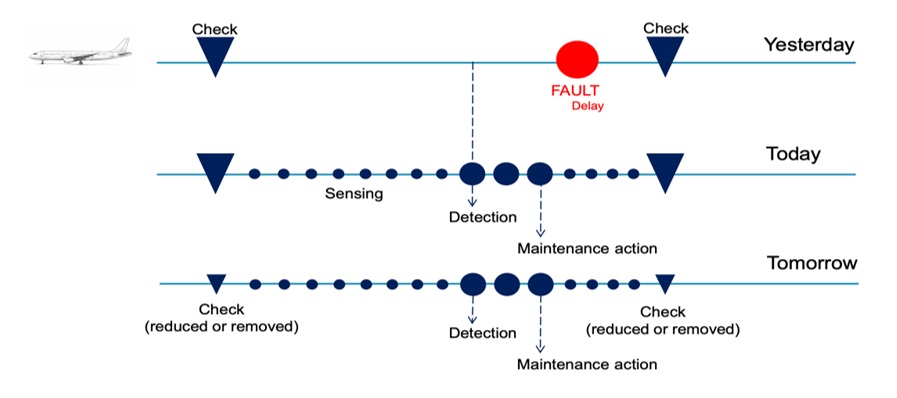

Preventive maintenance, which remains the industry norm today, is based on fixed inspection and overhaul intervals defined by calendar time, flight hours, or flight cycles, commonly structured into A, B, C, and D checks. Although this approach has proven strong safety record, it often leads to conservative maintenance decisions, early component replacement, and frequent inspections that are not always aligned with actual structural condition.

Fig: Aircraft Scheduled Maintenance Vs. Structural Health Monitoring

What Is Predictive Maintenance in Aviation?

Predictive maintenance represents the next step in the evolution of aircraft maintenance. Rather than relying on average service-life assumptions, it enables maintenance actions to be performed when required, based on the actual condition and predicted future health of aircraft systems and structures. This approach is particularly relevant for modern aircraft, where composite materials and complex structural behaviours demand condition-based assessment.

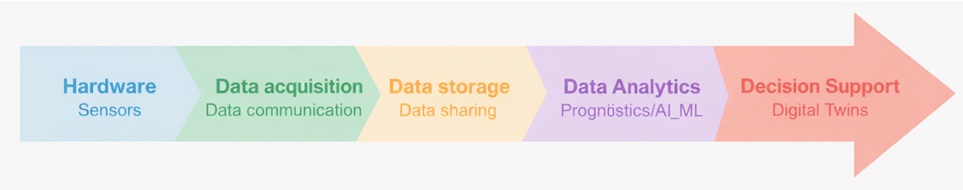

At its core, predictive maintenance is a condition-based, data-driven approach that integrates:

- Data collection from onboard sensors and connected systems that monitor structural, and mechanical parameters.

- Advanced analytics, including machine learning and hybrid physics-based models, to detect anomalies, and estimate Remaining Useful Life (RUL).

- Real-time monitoring and decision support, transforming health and prognostic data into actionable maintenance insights rather than raw information

- Improved safety: Through early identification of degradation and failure risks.

- Reduced Downtime: Predictive data enables proactive maintenance scheduling during planned ground time, minimizing operational disruptions.

- Improved Staff Planning: Airlines can better align maintenance workforce availability and expertise.

- Reduce Operational Costs: Lower unexpected downtime and improved efficiency reduce maintenance and operating costs.

- Better Asset Management: Predictive insights enable RUL estimation and optimized component replacement timing.

- Improved Regulatory Compliance: Predictive maintenance data supports compliance with regulatory requirements related to aircraft maintenance.

Why Predictive Maintenance Is Gaining Ground

Traditional maintenance strategies—run-to-failure and time-based preventive maintenance—have served aviation well but come with inherent limitations. Run-to-failure can lead to sudden disruptions, while strict preventive maintenance often results in unnecessary replacements and increased planned downtime.

Predictive maintenance bridges this gap by enabling intervention only when required, avoiding premature replacements while minimizing in-service failures. For airlines and MROs, this translates into improved aircraft availability, reduced maintenance spend, and more data-driven decision-making, and maximized asset life while minimizing both unplanned and planned downtime.

Recent studies indicate that unplanned downtime costs industries an estimated $50 billion annually, reinforcing the growing momentum toward predictive and condition-based maintenance strategies.

Closing the Loop Through CompSTLar

The transition to predictive maintenance requires an integrated framework that connects the entire aircraft supply chain. CompSTLar addresses this need by integrating manufacturing data, in-service usage, SHM outputs, inspection findings, and repair history into a lifecycle-oriented digital framework—a digital twin-driven Structural Health Monitoring & Assessment (SHM&A) framework that supports repair optimisation and enables cost-efficient predictive maintenance for composite aircraft structures.

As a CompSTLar consortium partner, Ziegler Aerospace contributes by bridging technological innovation with operational realities, supporting the development of condition-based MRO methodologies aligned with real-world maintenance environments.