Thermoplastic composites are gaining lot of terrain in the manufacturing arena due to its lightweighting and sustainability potential. Those are composed by a thermoplastic polymer matrix mixed with fibres that acts as a reinforcing element, providing the whole composite with very high mechanical properties. Automated fibre placement (AFP) composite manufacturing technology offers precise control of strong fibres to be placed on tool surface. This capability allows placement of fibre tows in customized paths which is not possible to achieve via other composite manufacturing methods while the mould tool gives precise shape of the composite component. This setup allows manufacturing composite with higher repeatability and process control, meanwhile generates highly efficient products tailored for each application.

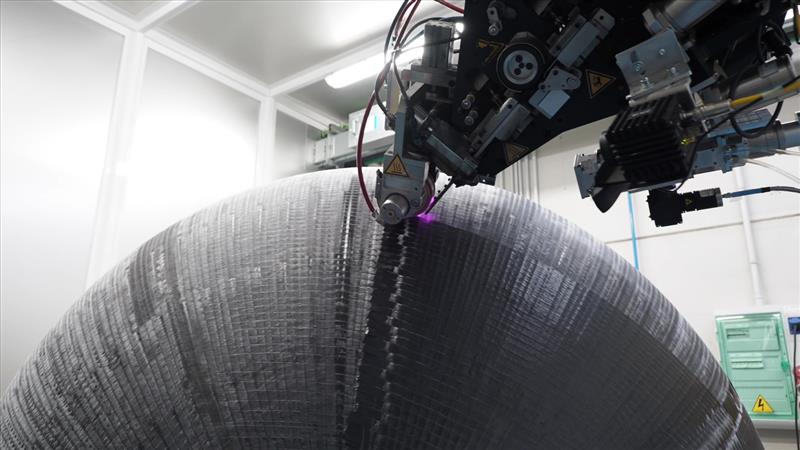

Figure 1: Fanuc 6 axis robot with 6 kW laser AFP system

Figure 1 shows the AFP setup at AIMEN. The tow placement is achieved via a placement head mounted on an industrial robot which can range from 6 axis up to 10 axis. Thermoplastic or thermoset UD tapes can be selected as input material which can be laid as individual or group of tapes. The most important aspect of any AFP system is imparting suitable pressure and temperature to the input tapes so that the matrix or binder melts adequately and sticks to the fibres. For applying pressure generally, a silicon coated roller is used but metallic/plastic rollers can be used as well in special cases where roller confirmability is not an issue. The temperature is provided by variety of sources such as IR lamp, gas torch, laser etc.

Within CompSTLar, AIMEN will develop advanced steered fibre composites, where the fibres are aligned along the complex stress paths in the Nacelle component of aircraft, thereby varying properties in desired locations and reinforcing where the composite strength is at its weakest. The variability in property is advantageous for next generation advanced aerospace and automotive composites where weight reduction and performance optimization are critical. However, steering often introduces challenges such as increased fibre waviness, gaps, overlaps, and poor adhesion, which can compromise mechanical properties. These issues can be mitigated through a reconsolidation step, involving the application of controlled heat and pressure to restore laminate integrity and reduce defects. This additional step enhances the in-situ consolidation of composites, thereby eliminating the requirement of autoclave or secondary post processing.