Modern aircraft are technological masterpieces. They are lighter, more efficient, and more sustainable than ever before. A major reason for this progress lies in the performance of advanced materials – especially thermoplastic fiber-reinforced composites. These high-performance materials combine low weight with exceptional strength and durability, making them ideal for aerospace structures. However, while they enable efficient flight, a crucial question remains: What happens to these materials at the end of their life cycle?

This challenge is at the core of the European research project CompSTLar. Together with partners from industry and research, we are working toward a future where aircraft structures are not only high performing, but also circular by design. Our approach goes far beyond new manufacturing technologies. It also includes smart repair strategies, maintenance concepts, and most importantly, innovative recycling routes that preserve the value of materials instead of wasting it.

- Why Composite Recycling Is So Difficult

Thermoplastic composites consist of a fiber-reinforcement (typically carbon fiber) embedded in a polymer matrix. This combination provides outstanding mechanical performance – but it also makes recycling extremely challenging. Today, three main recycling technologies are used in industry:

- Mechanical recycling, where components are shredded into low-grade fillers

- Chemical recycling, where the polymer is broken down to recover fibers

- Thermal recycling, where the matrix is burned off at high temperatures

While each of these methods has its place, they share a major limitation: the original material structure is destroyed. As a result, recycled materials cannot be reused in high-performance applications such as aerospace. This leads to downcycling – a significant loss of material value, functionality, and sustainability potential.

- From Recycling to True Circularity

A truly sustainable aviation industry requires more than just recycling. It needs closed material loops, in which materials remain in high-value applications over multiple life cycles. This is especially important in aerospace, where the production of high-performance carbon fibers is extremely energy-intensive and resource-demanding.

If we succeed in reusing existing material structures directly, we can significantly reduce:

- energy consumption,

- carbon emissions,

- dependency on virgin raw materials.

This vision is what drives the peel-based recycling process for UD-tapes developed by Fraunhofer IPT within the CompSTLar project.

- Tape-REx: High-Value Recovery Instead of Downcycling

Instead of destroying composite at the end of life (EoL), our recycling approach follows a fundamentally different strategy. The goal is to recover semi-finished unidirectional (UD) tapes directly from thermoplastic composite products.

UD tapes are key building blocks in lightweight construction. In these materials, the fibers are precisely aligned in one direction to carry high mechanical loads – making them ideal for aerospace structures. Recovering them in functional form offers decisive advantages:

- The fiber orientation is preserved

- The mechanical performance remains high

- The recovered tapes can be directly reused in new components

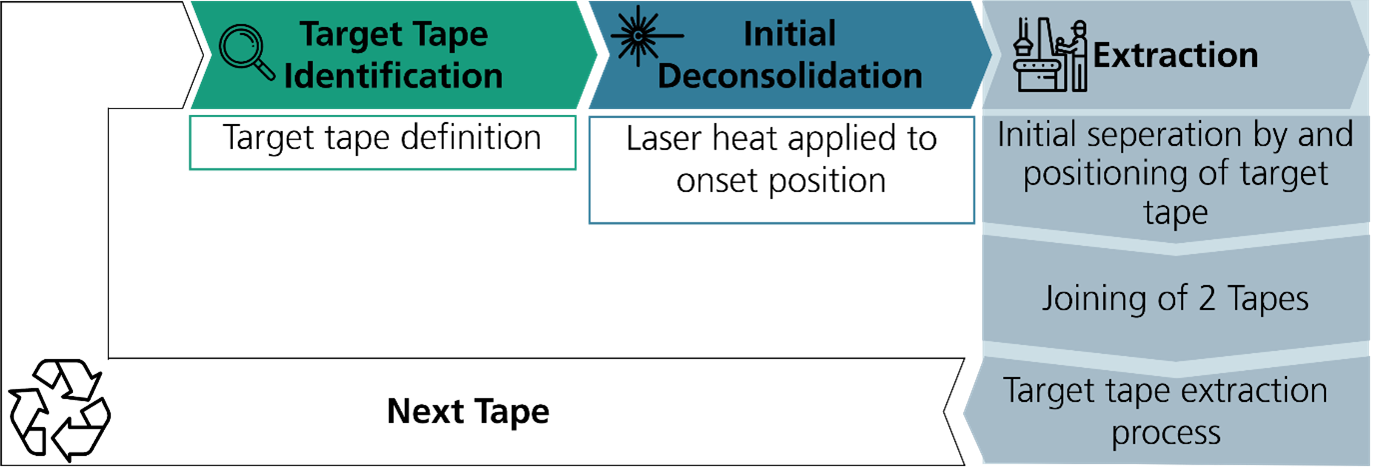

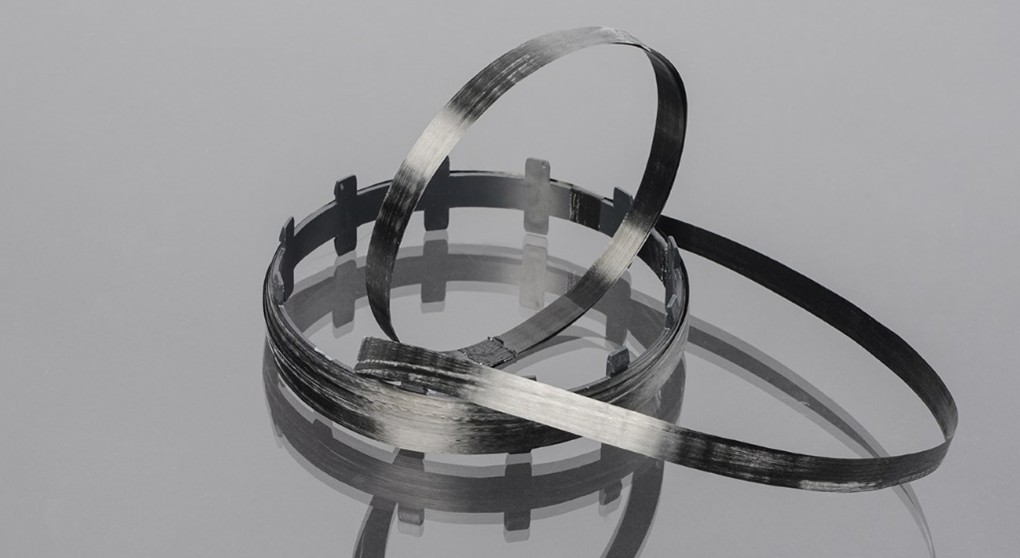

This turns recycling into high-value material recovery and represents a major step towards a truly circular composite economy in aviation. The process concept is visualized in figure 1 and a Recycled UD-Tape reclaimed from a ring specimen is displayed in figure 2.

Figure 1: Concept for the recycling process

- The Science Behind the Process

Recovering usable UD tapes from composite products is scientifically demanding and the discontinuous use of UD Tapes in AFP laminates impose an additional challenge for the recycling process. The fibers must remain undamaged, while the thermoplastic matrix must be reshaped in a highly controlled manner. Temperature, pressure, and processing time all have a decisive influence on the final material quality because controlling these parameters defines the recycling process and its outcome.

Additionally, the evaluation of the tape characteristics focuses on the material-scientific perspective on recovered and virgin tapes. This includes:

- Mechanical testing to assess stiffness and strength

- Geometric characterization of the recycled tape

- Microscopic analysis to evaluate and compare the tape cross-section

Only if the recycled tapes meet strict performance and safety requirements, they can realistically be reintegrated into aerospace production chains.

- Sustainability Across the Entire Lifecycle

What makes CompSTLar truly special is its holistic lifecycle approach. The project does not focus on recycling separately but connects all stages of a composite component’s life:

- Advanced manufacturing methods for efficient production

- Smart repair and maintenance strategies to extend service life

- Innovative recycling technologies to close the loop

By linking these aspects, the project redefines how thermoplastic aircraft structures are designed, used, maintained, and reused.

- Why This Matters – Especially for the Next Generation

The aviation sector is under increasing pressure to reduce its environmental footprint. Lightweight composite materials will continue to play a key role in the transformation to a climate-neutral planet. The key question is whether we can use them responsibly over multiple life cycles.

It combines cutting-edge technology, real environmental impact, and strong industrial relevance. Sustainable aviation is not only a technical challenge – it is also a societal one.

- Looking Ahead

Through CompSTLar we are taking concrete steps toward a circular economy for high-performance aerospace materials. If successfully implemented at industrial scale, this approach could drastically reduce raw material demand, lower the carbon footprint of aircraft production, and create new value chains for recycled composites. Sustainable aviation does not end with efficient flight. It begins with how we design, use, repair, and reuse the materials that make flight possible.

Figure 2: Recycled UD-Tape extracted from a ring specimen