Think of a carbon fibre tow as a tightly braided strand of hair and the thermoplastic resin as a thick, glossy varnish. If you want that varnish to reach every single hair, you first have to comb the braid open. In a thermoplastic impregnation line, that “combing” step is tow spreading, and it quietly decides whether you end up with high-quality, thin UD-tapes or a bundle with hidden dry spots and defects.

A carbon fibre tow arrives at the line as a dense, compact bundle. On the outside it looks neat and uniform; inside it is so tightly packed that molten thermoplastic struggles to reach the filaments in the centre. If you simply pull that compact tow through the resin and hope for the best, the outer fibres are well coated, but the inner ones may remain partially dry. For non-critical applications you might get away with that. For aeronautics, you absolutely don’t.

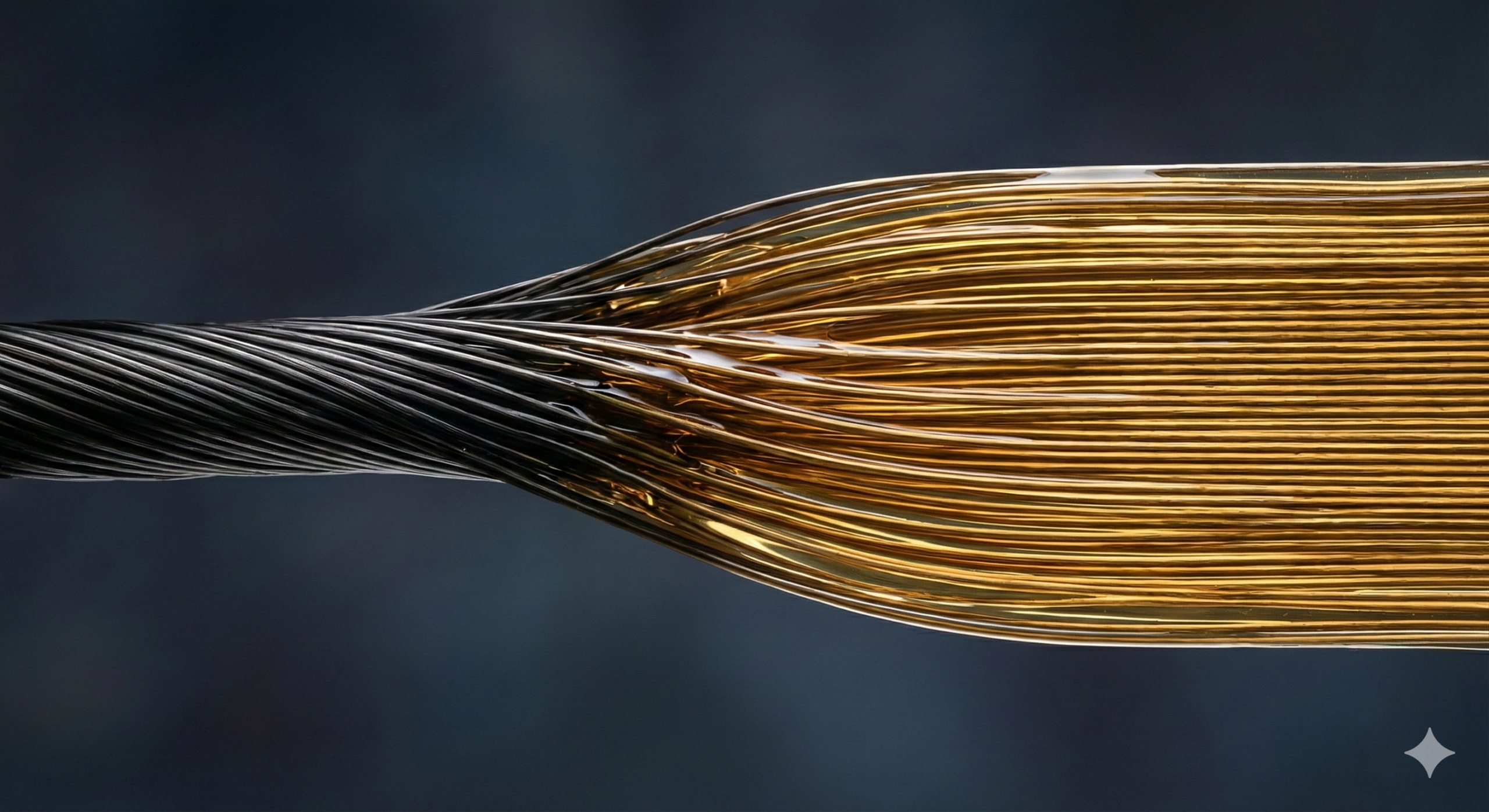

Figure 1: The combing effect’ in action: A compact carbon fibre tow is gradually spread open as it navigates the guide rollers, preparing it for optimal resin impregnation.

Tow spreading is the moment the compact bundle is gently opened into a wider, flatter ribbon. Through carefully designed rollers, guides or other spreading devices, the individual filaments are separated just enough to create micro-gaps between them. Suddenly the resin has a much easier job: it can flow around and between fibres instead of fighting its way into a tight core. The distance it has to travel to reach the centre of the bundle shrinks, and impregnation changes from a slow, difficult process to one that can be fast, efficient and repeatable.

Once the tow is properly spread, you can achieve UD-tapes that are both thin and rich in fibre. The same number of filaments is distributed across a wider width, and after melt impregnation and calendering, the tape that emerges is flat, smooth and much thinner than what you would get from an unspread tow. For the engineers downstream, this has immediate benefits: the tapes conform better to curved surfaces, stack into laminates with very predictable thickness, and feed more reliably into automated placement heads. In practice, that means fewer gaps and overlaps, more stable process windows and laminates whose mechanical properties are not only high but consistent from part to part.

From an industrial point of view, proper tow spreading is also a productivity tool. An impregnation line has to run at meaningful speeds to be economically viable. If the tow stays compact, you either accept poor impregnation or slow down the line and increase pressure and temperature to push resin into the core. That can damage fibres, consume more energy and still fail to eliminate voids. A well-spread tow, by contrast, acts like a fast, open highway for the resin: it allows good impregnation at reasonable pressures and temperatures, supporting higher line speeds without sacrificing quality.

This is why AIMPLAS, the Plastics Technology Centre in Spain, is devoting so much attention to tow spreading in its thermoplastic UD-tape work. Within the EU project COMPSTLAR, AIMPLAS is upgrading the tow spreading system in its impregnation setup with a clear purpose: to produce high-quality, multifunctional UD-tapes specifically tailored to aeronautic requirements.

COMPSTLAR aims at advanced thermoplastic composites that can do more than just carry load. The project explores materials with added functions such as electrical conductivity, lightning strike protection or integrated sensing. To make that realistic at the industrial level, the underlying UD-tapes need to be extremely well controlled: stable fibre distribution, low thickness, excellent impregnation and the ability to host additional fillers without creating weak, resin-rich spots.

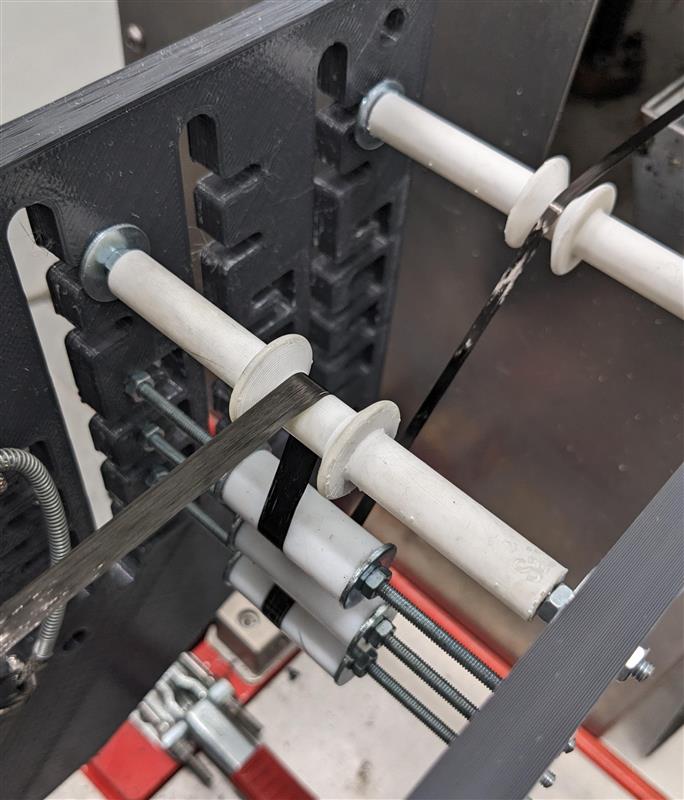

By enhancing their tow spreading system, AIMPLAS is tackling this challenge at its source. Finer control of tow width and areal weight ensures that the number of filaments across the tape remains consistent along its entire length. Improved tension management and spreading devices open the tow uniformly without damaging the fibres. As a result, the melt impregnation stage receives a tow that is already in the ideal configuration for resin to penetrate quickly and thoroughly.

The payoff is felt all the way down the value chain. In automated tape laying for aeronautics, robots depend on tapes that behave predictably: constant width, repeatable thickness, steady stiffness. Variations can lead to local defects that slow production or compromise quality. The upgraded tow spreading at AIMPLAS helps deliver tapes that are far more compatible with these fast, precise manufacturing methods. And when multifunctional fillers are introduced, a well-spread, well-impregnated base tape makes it much easier to distribute them evenly and preserve mechanical performance.

In the bigger picture, this might look like a minor, technical upgrade to a piece of equipment in a production line. In reality, it is one of the quiet enablers of lighter, smarter and more sustainable aircraft structures. Better spreading leads to better impregnation and thinner UD-tapes; better tapes support faster, more reliable automated manufacturing; combined with the inherent advantages of thermoplastic matrices, this pushes aeronautics toward cleaner, more efficient production routes.

It all comes back to that simple idea: if you want every fibre to share the load and every filament to be properly protected by the matrix, you cannot ignore how the tow is prepared before impregnation. AIMPLAS’s work in COMPSTLAR shows that by perfecting something as deceptively modest as tow spreading, you can turn a strip of black UD-tape into a sophisticated, aeronautics-ready material—thin, multifunctional and ready to fly.